"We need to transform our design using configuration approach. Could you refine the design with minimized cost?"

Toyota Motors North America

Project Overview

Toyota Motors North America (TMNA) partnered with IBM to modernize its vehicle configuration platforms, which support the capture, fulfillment, and administration of vehicle orders across multiple internal systems. The challenge was to refine and evolve existing configuration workflows (not redesign from scratch) while minimizing operational cost, reducing friction, and supporting Toyota’s growing vehicle offerings.

This project required deep platform thinking, close collaboration across large teams, and UX decisions grounded in real operational constraints.

As a senior UX designer, I joined a large, distributed design team (7+ designers), each responsible for different core platforms within TMNA ecosystem.

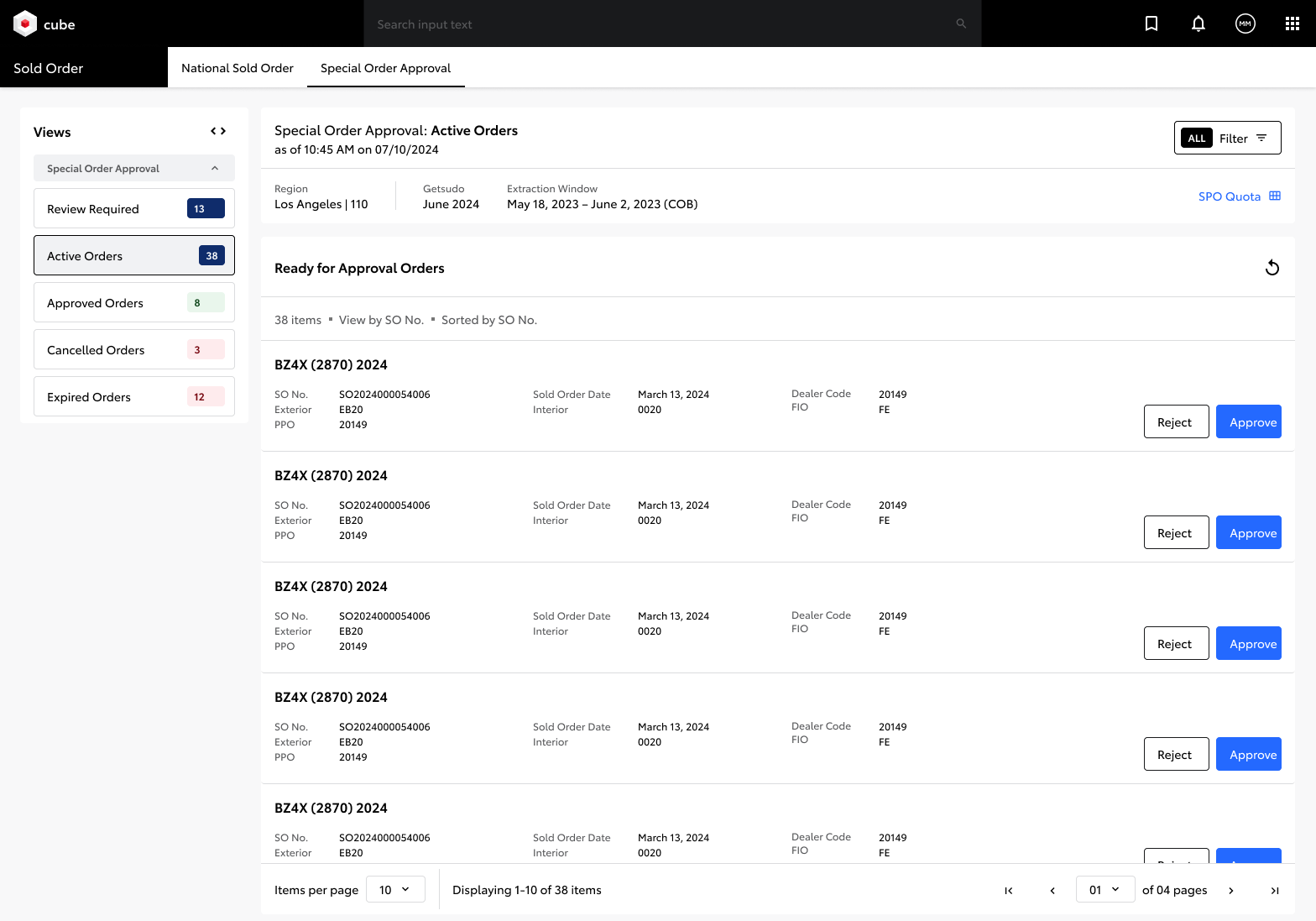

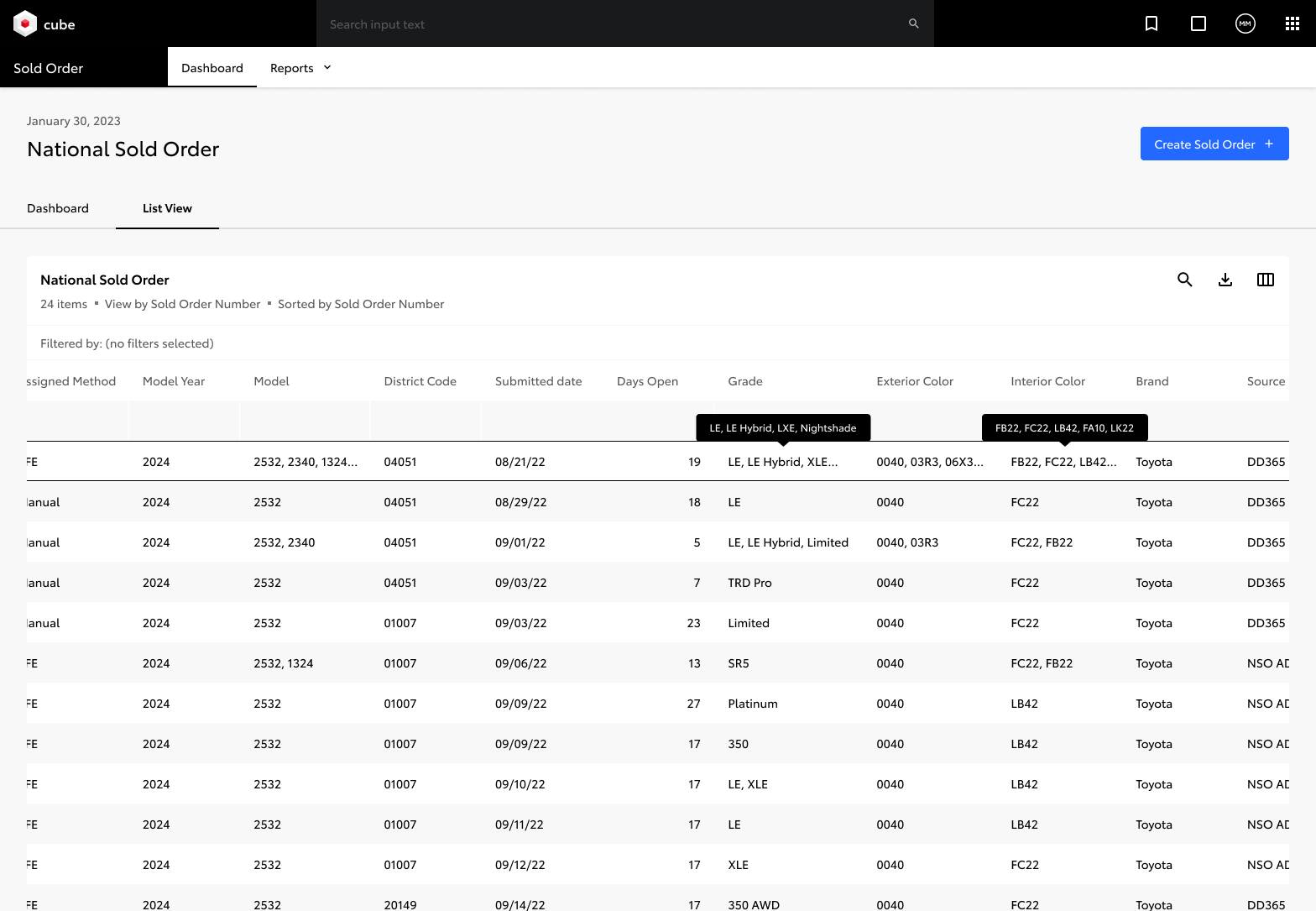

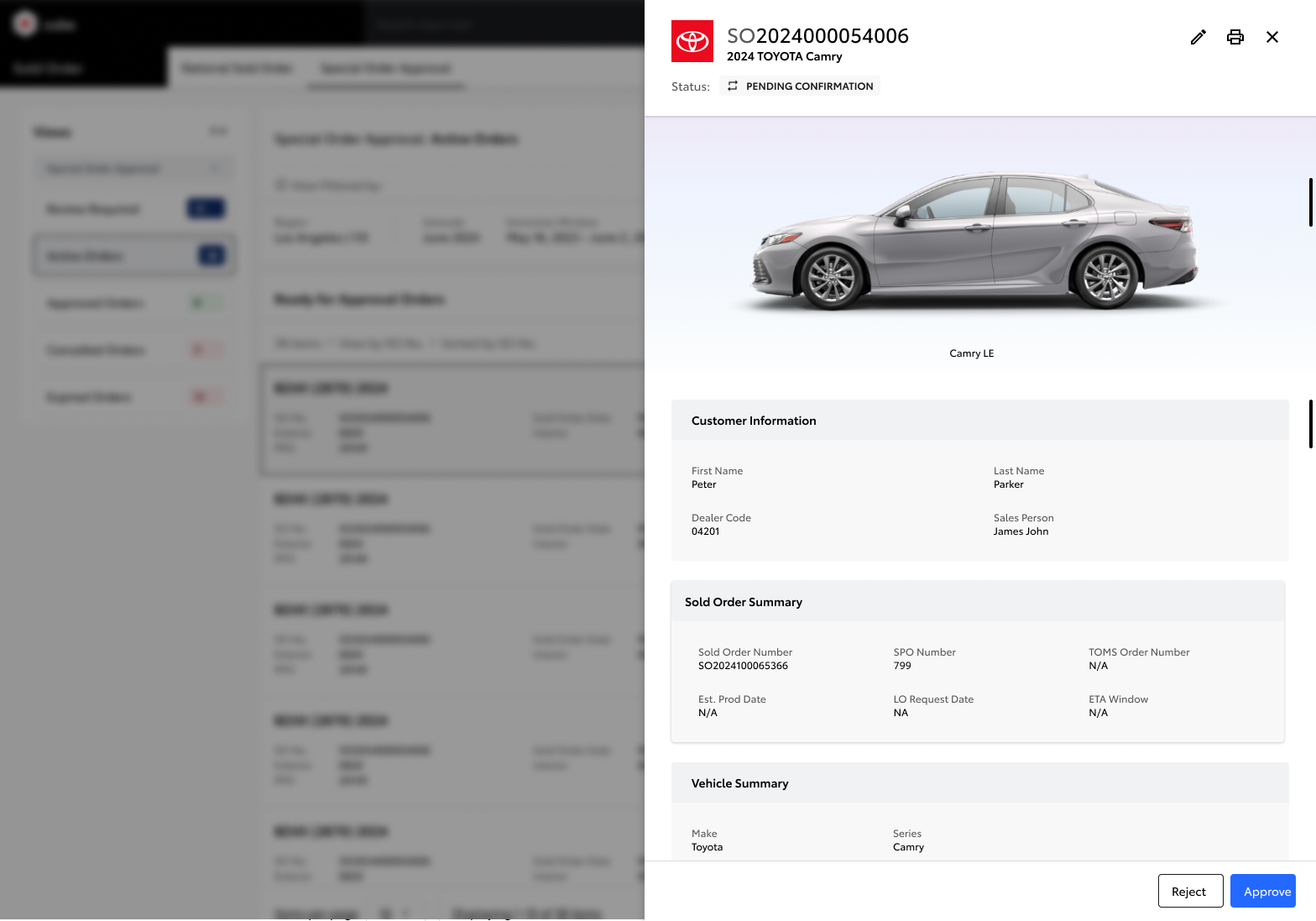

Leading UX design for National Sold Order (NSO) and Smart Fulfillment Engine (SFE)

Collaborating closely with product, engineering, and business stakeholders

Refining existing workflows

Designing high-fidelity solutions aligned with technical and operational constraints

About the Client

TMNA oversees vehicle manufacturing, sales, and distribution across the U.S. and Canada. As one of the largest automotive manufacturers globally, TMNA operates complex internal systems to manage vehicle configuration, ordering, and fulfillment at scale.

IBM supported TMNA by helping modernize internal tools, called TMNA Cube, used by dealers, operations teams, and internal stakeholders to improve visibility and efficiency.

The Challenge

TMNA’s configuration platforms had grown over time to support new vehicle options, markets, and business rules. While powerful, these systems had become increasingly difficult to use and maintain.

Key challenges included:

Multiple legacy platforms with inconsistent UX patterns

The need to improve usability without disrupting existing workflows

Pressure to deliver improvements while minimizing development and operational cost

The goal was to evolve the system, not reinvent it.

My Role

Design Approach

Evolving, Not Replacing, Existing Systems

Given the scale and risk involved, the design approach focused on incremental improvement rather than full replacement.

Preserving familiar workflows while reducing friction

Clarifying complex rules through better information hierarchy

Reusing and refining existing patterns to minimize engineering overhead

Designing for Scale and Accuracy

Configuration errors can have significant downstream impact. I focused on:

Structuring dense data into readable, task-oriented layouts

Designing interactions that reduce cognitive load and error risk

Supporting edge cases without overwhelming primary workflows

Ensuring designs aligned with real-world operational processes

Outcome

Cross-Functional Collaboration at Scale

Working within a large, cross-functional team required strong coordination and communication.

Regular meeting with stakeholders to get approval for UX decisions

Regular meeting with product managers to align UX decisions with business priorities

Real-time design meeting with engineers to ensure feasibility across legacy and modern systems

Weekly cross-team design review sessions to align direction, share learnings, and maintain cohesion across the broader program

The refined UX designs improved usability across TMNA’s configuration platforms while respecting operational and technical constraints.

Reduced friction in high-frequency operational tasks

Improved consistency across related platforms

A scalable UX foundation to support future vehicle programs and enhancements